Ice Harvesting from the Hudson River

Webpage by Cliff Lamere 16-21 Feb 2009, revised 25 Apr 2010

![]()

The Albany Evening Journal, February 20, 1915, pg 5

ICE HOUSES IN THIS VICINITY WELL FILLED

------

Dealers in New York and Albany Confident They Can Meet Demands -- Schodack Landing's Big Storage.

------

Ice dealers in Albany and New York say that there is little need to worry about next summer's supply. Those in Albany and vicinity who cut from ponds and still water have been able to get their usual supply with a prospect of adding more before the winter ends. The dealers who cut on the river have not been so fortunate. Some

in this city have not been able to secure a crop; others who cut at Castleton and down the river points have done better.

ln New York it is expected that the shortage in the Hudson river crop will be made up from Maine and other places. The makers of artificial ice will also come to the rescue and the shortage will thus be eliminated.

A dispatch from Schodack Landing says that ice dealers in that vicinity believe the season is practically over. At a conference held yesterday, William I. Gardenier of Gardenier & Sons, and James Scott of the National Ice company were of the same opinion. Each company has secured about 50,000 tons, while the Knickerbocker company's house here has about half that amount. Edward McCabe has 20,000 ton, mostly held over from last year, which makes a grand total of nearly 150,000 tons housed on Schoharie [sic] creek. Houses on the main river have very little.

[ Schoharie creek should be Schodack creek which "is a tidal channel which separates the islands from the mainland, on which stands the community of Schodack Landing."

Source of this

statement: "Historical and Archeological Resources of Castleton Island State Park, Towns of Stuyvesant, Columbia County, New Baltimore, Greene County, and Schodack, Rensselaer County, New York: A Preliminary Phase I Cultural Resources Assessment"

by Paul R. Huey, May 1997 ]

[Note: Comments above in square brackets [ ] are mine.]

![]()

Ice harvesting along the Hudson River was an important business during the 1800s and very early 1900s in Rensselaer and Greene Counties of New York State. It employed thousands of men, including farmers in their off-season. There was a large summer demand for ice, especially by New York City. Being so close to the ocean, however, Hudson River ice in the New York City area contained too much salt to be useful. It resisted freezing, and it melted quicker than freshwater ice.

The Hudson River has tides from New York City all the way north to Troy in Rensselaer County (it is a tidal estuary). That water, over 150 miles in length, is all at sea level. Freshwater flowing into the Hudson at the northern end of the tidal section tends to keep the salt water out of the Hudson, but not entirely. Salt water from the ocean is able to reach Poughkeepsie in Dutchess County by flowing along the bottom of the river (saltwater is heavier). There is some mixing of the two layers of water. During drought years when there is less freshwater to keep it out, the salt front can creep even farther north. The river water at Greene and Rensselaer Counties is entirely freshwater which made the Hudson River in that section so suitable for ice harvesting.

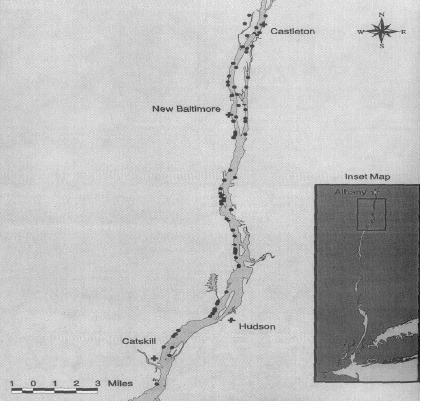

The map below shows the locations of icehouses from Catskill (Greene Co.) to Castleton (Rensselaer Co.). Across from Castleton were some icehouses in Albany Co., and opposite New Baltimore (Greene Co.) were some in Columbia Co. The dark inset map shows a rectangle just south of Albany. It outlines the area depicted in the lighter map. The Atlantic Ocean and the western end of Long Island are at the lower right of the inset.

[Source of map: "Towards an Archaeology of the Hudson River Ice Harvesting Industry" by Harris, Wendy Elizabeth & Arnold Pickman]

The Town of Bethlehem is in Albany County across the Hudson River from Castleton. The Bethlehem website has the following to say:

"The shores of the Hudson River in Bethlehem were lined with icehouses. Some, like George Bestís Cedar Hill Ice House were locally owned and shipped their ice to New York City. Others were owned by large companies like the Knickerbocker Ice Company out of NYC. Wilburís Ice House on the Normans Kill served the Albany market. In 1855 Hunts Merchant magazine reports that NYC required 285,000 tons of ice, Albany stored up 20,000 tons. These figures were only to grow, before a steady decline in the 1920s."

The Medical Record, A Weekly Journal of Medicine and Surgery. Vol. 31, January 1, 1887 -- June 25, 1887. pp 347-349, said the following:

"New York City. -- The ice which is supplied to New York City, and to a certain extent to Brooklyn and Jersey City, comes almost entirely from three sources -- from the Hudson River, from a few lakes and ponds adjacent to the Hudson or near the line of some of the suburban railways, and from Maine. The Hudson River stands foremost as a source of supply...

The Hudson River. -- We now come to the great and most important source of our ice-supply -- the Hudson River... The main ice-harvesting fields lie between Poughkeepsie and Troy, and their exact location within these limits is determined by a variety of conditions, such as dockage facilities, currents, widenings in the river, ownership of water-front etc. The water must be deep enough, so that the ice will not be contaminated from the bottom by grass, sand, etc. Areas of water in which the currents are not too strong are sought after, as during mild winters the requisite thickness of ice is more certain to form where the currents are not excessive. In prolonged cold weather, however, the river freezes completely over, so that ice may be cut in the deeper channels as well as elsewhere."

All around the state, New York's ponds and lakes were an important source of ice for local consumption. We owe our many ponds and lakes to a visit over 10,000 years ago of a continental glacier that covered the entire state at that time. In various ways, the glacier causes the formation of about 7000 lakes in the state.

The Hudson River icehouses stored ice from both the river and from nearby ponds and lakes. From the icehouses, much of it was shipped by boat to New York City, which consumed part of it. They, in turned, transported some of it to other states and countries. It is known to have been taken as far as to India. At the end of the Civil War, as much as three million tons of ice was being stored in the Hudson River Valley during the winter months.

![]()

Ice Harvesting - The Details

New York's freezing temperatures in winter cause the ponds and lakes to form a layer of floating ice at the surface. Sub-freezing air temperatures draw heat out of the ice, which in turn draws heat out of the liquid water in contact with the bottom of the ice. The result is that more ice crystals are added to the bottom of ice, thus making the ice layer gradually thicker and thicker. All of this ice is a clear ice.

Snowflakes fall on top of the ice. They can fuse with each other to form ice when the air temperature gets above freezing, or if it should rain on the ice on a warm day. Instead of being clear, this ice is white because of the trapped air that had been between the snowflakes. White ice has less ice in each block, so it had less value than clear ice. Businesses wanted clear ice.

Since the snow ice melted quicker (it contained less ice) and was less marketable, it was a common practice to periodically scrape the snow off the ice, as well as on the day of the harvest.

A technique used to speed up ice formation on the Hudson was to drill holes in the ice. If the Hudson River tide was rising, the upward pressure of the water on the ice would cause water to flow up through the holes and out onto the ice. That clear water would freeze to add thickness to the clear ice.

Before ice could be cut from a pond, lake, or river, it had to be checked to see if the ice was thick enough. Notice the long-handled augur in the next photo. It could quickly drill a small hole in the ice.

[Source]

[Source]

If the ice was of a proper thickness, the surface had to be cleared with a snow scraper that was pulled by a horse or team of horses.

Removing surface snow with Scraper c1907. [Source]

Removing surface snow with Scraper c1907. [Source]

Then, a very long straight, shallow cut about Ĺ inch deep was scribed along the edge of a board. The length of the line could be extended to 200 feet or more by moving the board many times and carefully aligning it with the previous position.

In the next photo the left side rests in the previous Ĺ-inch cut and guides the saw so that it makes another straight, parallel cut. The cutting blade is on the right side of the device. Notice that the man is holding the handles of what is very much like the old horse-drawn farming plow. This one, however, had a shallow cutting blade at the bottom of it. The man's feet straddle the new cut, and the rope or chain from the horse is only attached to the right side of the device. This is evidence that the cutting occurs only on the right side of the device.

[Source]

[Source]

After making the parallel lines that establish the width of the eventual blocks of ice (about 22 inches apart), additional Ĺ inch deep cuts must be made across the original lines in order to determine the length of each block (up to 44 inches according to one source).

Next, a different horse-drawn saw called a plow, or ice plow, was used to deepen the cuts. Like the tool above, it also had plow handles (see next photo). There were two large teeth on each blade of the plow. The plow was resting on the top of the ice at the moment this photo was taken. The curvature of each blade would probably have helped bring the ice shavings up to the surface out of the way of the next blade. It took more than one pass along a line to cut to the full depth of the plow's saw.

[Source]

[Source]

The next photo on the Hudson River in 1912 shows an ice plow ready to be pulled by a horse. The man on the right will lead the horse to make sure it goes straight. Depending on the size of the ice field, it could take many days to make all of the cuts. Therefore, it was important that the plow's saw blade did not cut through the bottom of the ice. If water got into the cut, it would freeze shut again before the individual ice blocks could be separated from each other.

[Source]

[Source]

Horses had to relieve themselves during the workday, which meant that their urine and feces had to be cleaned off the ice. Formaldehyde was used to remove the wastes.

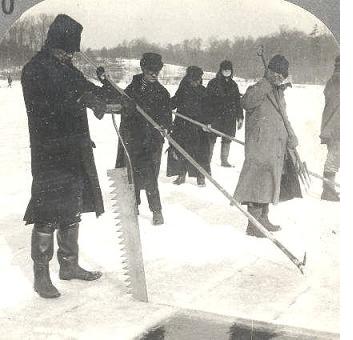

When it was time to separate the

blocks of ice from each other, a very long two-handed ice saw was often used

to finish the cuts. In the photo below, the ice may

look very thin, but normally about 8/9ths of the ice is below the water

surface. These men are quite safe. The preferred thickness of ice

for harvesting was

14-16 inches, but that thickness might not be achieved in winters when the ice

started to form later than usual. In colder winters, the water would freeze

sufficiently to form a second crop.

a second crop.

[Source]

[Source]

[Source]

Ice Hook

[Source]

Ice Hook

An ice hook had a sturdy metal tip and was attached to a long wooden pole perhaps eight to ten feet in length (notice the wood at the left edge of the photograph). The hook could grab into a block of ice to pull it or push it, or the hook could be put down the side of a free-floating block to push it. The straight point was also used for pushing. How the ice hook was used often depended on the distance from the worker to the block of ice.

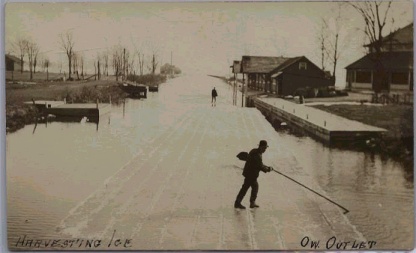

The strategy used to get the ice to the shore depended on the size of the operation. Blocks of ice were separated sometimes in a straight line back to shore where there might be a conveyor belt awaiting them. The block nearest shore was removed first, then the next block, and so on. The floating blocks could be pulled to shore one at a time along an open channel by a horse or a man with an ice hook. Over time, the channel got wider and wider as more rows of ice blocks were removed.

In larger operations, guiding one block at a time was too slow. Instead, a large section of partially-cut blocks, called a float or pack, was separated from the other partially-cut blocks. If the water was shallow enough, the entire float was guided by a man with a long pole. He might even stand atop the float while trying to guide it. The next photo shows men at opposite ends of a long float. Both have poles in the water. The float has been pre-cut into blocks to make separating them easier when the men get the floating mass to its destination.

[Source]

[Source]

The next photo was taken in 1912

somewhere in New York State [Source].

The ice float is being pushed to the right by the man at the left edge of the

photo. Floating  in a narrow channel or

"canal," it slowly moves past three men standing on a barring bridge, a temporary

structure set up on posts. The men are separating rows of ice blocks from the

float, or possibly every other row. The tool they used for this, called a

breaking bar or breaking-off bar, looked like a three-pronged fork. It

helped them to chip through the ice at the bottom of the cuts. If

the ice was not too thick, hand saws could sometimes be avoided.

in a narrow channel or

"canal," it slowly moves past three men standing on a barring bridge, a temporary

structure set up on posts. The men are separating rows of ice blocks from the

float, or possibly every other row. The tool they used for this, called a

breaking bar or breaking-off bar, looked like a three-pronged fork. It

helped them to chip through the ice at the bottom of the cuts. If

the ice was not too thick, hand saws could sometimes be avoided.

Due to their heavy weight, many of these bars were lost when a worker lost his grip on it as the bar chipped through the bottom of the ice.

Behind the men in the photo is an ice house which has two conveyor belts in operation. Here is my guess as to what is happening in the photo. It looks like the men shown are separating the float into separate rows of connected blocks. Off to the right, there is probably a channel in which the ice is pushed toward land. There are probably barring bridges there also. Those men would separate the rows into individual blocks which were then guided onto one of the two conveyor belts. This is only one possible scenario.

A large ice house might store 50,000 tons or more of ice. Between harvest and reaching the consumer, 50% or more of the ice might melt away. Efficient icehouses could keep this loss to only 20%. Many icehouses were painted white to reflect the sun's rays and reduce the warming of the ice within. And they had double walls and ceilings filled with sawdust, wood chips or sometimes hay. Packing these materials around the ice also reduced melting during storage.

Sawdust was put on the floor (for insulation and to keep the ice from sticking to the floor), and a layer of ice was placed on top of it. That layer was covered with sawdust, then another layer of ice was put on top of the sawdust. This continued layer after layer. When the top layer was set in place, the entire mass was covered with sawdust. The sawdust between layers did not function as insulation, but rather was used to keep the blocks of ice from fusing with each other. Ice blocks in contact would do that as a result of pressure caused by the weight of the ice blocks above it.

It is interesting to note that in good ice years, more ice could be harvested than could fit in the ice houses. In that case, the ice blocks were stacked outside the houses for use early in the season. Those stacks needed only a temporary cover of boards.

![]()

The 1915 article at the beginning of this webpage is about ice harvesting in southernmost Rensselaer County. However, a method of manufacturing ice had been invented in 1910. That would soon make the harvesting of natural ice an obsolete occupation. The ice could be manufactured near the place where it would be used, which was a great advantage. Losses due to melting were much reduced, and the cost of a great deal of labor was saved.

In addition, the first electrically-operated refrigerator was produced in 1915. However, many people could not afford them. I remember the ice man delivering ice to our home in the early to mid 1940's. It was no doubt manufactured ice that he brought.

A great deal of ice harvesting was done in New Baltimore, in northernmost Greene County. When natural ice was no longer harvested, the windowless icehouses were converted for the growth of mushrooms which like a dark and damp environment. Frangella's mushrooms grown there became well known locally and beyond.

Note: With two exceptions, I could not find good photos taken in New York State to show each step in the ice harvesting process.

![]()

January 17, 1894

New York Times [Source]

COLD WEATHER IS WANTED.

Then the Ice Harvest in the Hudson Will Begin.

A few days of cold weather are greatly desired by the dwellers along the Hudson River. A week of such weather as was experienced in the latter part of last week would open up an industry which would at once give employment to many thousand men, cutting ice and stowing it in the houses which are scattered thickly at almost every town.

It is estimated that in ice harvesting from 20,000 to 25,000 men would find employment this season.

Some of the smaller dealers are reported to have begun operations. Measurements at Coxsackie on Saturday showed a thickness of from five to six and a half inches, and at that place the fields had been scraped and flooded.

The total yield of ice from the Hudson is upward of 3,500,000 tons, most of which finds its way to this city.

It is said there is little fear from lack of ice this year, although the weather has been so mild thus far that work is later than usual. Last year the first cutting of any importance was done in the last week of December. The ice harvest is greatest along that stretch of river between Poughkeepsie and Troy.

The Albany Argus has prepared a tabulated statement, showing the capacity of the icehouses from Troy and West Troy to Poughkeepsie and Marlborough, from which it appears there are 145 houses with a capacity, in round numbers, of 3,040,000 tons.

Hand Saw

![]()

Read an article called Hudson River Valley Icehouses and Ice Industry.

Visitors since 21 Feb 2009